- Download E-catalogue

- Get new product information

- Get Special offer

- Get promotion information

- Registered MemberClick here to login

LOG ON

DON’T HAVE AN ACCOUNT YET?

Having a DANAU account will give you access to:

Having a DANAU account will give you access to:

Please leave your email, we will promptly send your login account and password

We will contact you within 24 hours.

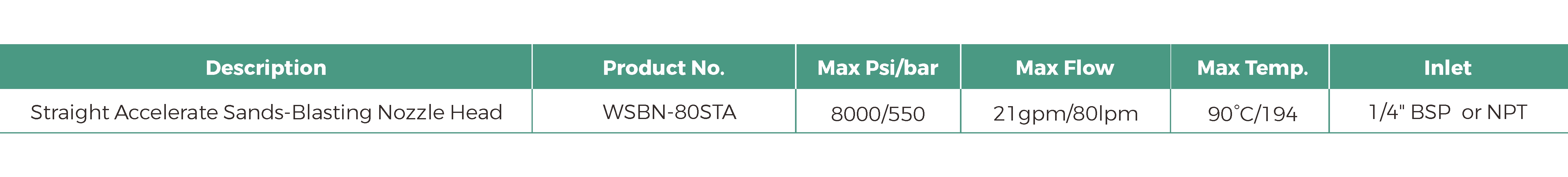

STRAIGHT ACCELERATE SANDS-BLASTING NOZZLE HEAD

Wet sands blasting works by adding abrasive media into the high pressure water jet with high velocity that drastically increases the mass and impact energy. The main benefits of the wet sands blasting that is much faster process; water prevents friction and will not warp metal through the production of heat from friction; wet abrasive blasting also know as dustless basting that significantly lowers dust emissions due to the element of water being added to the process. Sandblasters are suitable for dust-free blasting of the following solids with a grain size ranging from 0.2 to 1.5 mm such as Mineral blasting agent(sand), Sodium Carbonate (water-soluble), Slag(fine or coarse), Glass beadsand powder.

VIDEOS